LIVE from Fruit Logistica: TOMRA showcases new premium sorting machine

VU | TOMRA Food

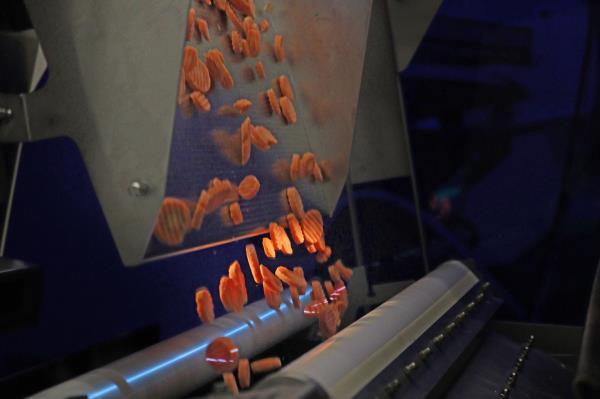

Today, at Fruit Logistica Berlin, TOMRA Food presented the TOMRA 5C premium sorting machine, with its special biometric signature identification technology, for frozen Vegetables. Visitors could watch a live online demonstration of the sorter in action at TOMRA’s Test Center in Leuven (Belgium).

By placing the TOMRA 5C on the processing line between the packing station and the IQF tunnel, final checks for food safety and product quality can be carried out with the highest accuracy. As the frozen veg reaches the end of the line for bagging, the sorter recognizes and eliminates remaining foreign material, extraneous vegetable matter (EVM), and product defects which are hard to detect (stems and stalks with green beans and nightshade with peas). Its detection capabilities significantly reduce the risks of product recalls and consumer complaints.

The TOMRA 5C delivers other operational advantages. Compared to its predecessor, the Nimbus BSI, this new machine further boosts sorting efficiency and yields; is simpler to keep running in optimum condition; has a new design which reduces cleaning time by up to 35% compared to the Nimbus, and has a capacity that's higher by 5-10%.

The machine was first showcased in 2020 to sort Dried Fruit and Nuts but was designed from the outset for many different applications, including IQF Veg and Fruit. This machine is now being made available for IQF lines following tests with one major IQF Veg processor in Europe and another one in the United States. Validation was conducted during 6 weeks, with the machines working for 2 shifts per day minimum and sorting 4 to 5 tons of product per hour. Sorting performance was evaluated by testing over 20 different types of vegetables, mono and mixed.

The trials showed excellent results - even with veggies that are normally difficult to sort, such as white cauliflower, and even when looking for hard-to-detect foreign materials, such as nightshade mixed in with peas.

High efficiency and performance

Sorting accuracy of the TOMRA 5C's is made possible by combining high-resolution lasers with the new Biometric Signature Identification (BSI) technology, which guarantees that each object passing down the line is assessed not only for its color and shape, but also biological features. This spectral imaging is capable of looking inside materials on the line by identifying their ‘fingerprint’ or biometric characteristics. BSI clearly differentiates good and bad materials and can detect even smaller defects than those recognized by ordinary spectral technology.

Efficiency is also enhanced by connectivity to TOMRA Insight, the cloud-based data platform. By accessing live data from the sorter, operators can make quick improvements to line efficiencies. While operating with mixed frozen vegetable products, this facility can guarantee that each bag is packed with the right mix. In addition, accessing data retrospectively enables it to quantify the standards of raw materials from suppliers and to make better-informed decisions.

Heartbeat feature empowers to maintain the machine's optimum performance. This option gives one-click information about the machine's health status and automatically triggers alarms if there are faults. Cleaning is now easier and uptime is increased due to a hygienic machine design with minimal and curved surfaces and easy access. Operation is made easy with the TOMRA ACT user interface. This machine has proven in validation that it can withstand the tough conditions found in IQF environments, with an ability to perform well in temperatures as hot as 50°C or as cold as -30°C.

Visit TOMRA Food at Hall 09, C-03

For more details about TOMRA 5C, send your inquiry today