Fruit sorting passes to the next level with the innovative technology by GP Graders

VU | GP Graders Pty Ltd

For over 58 years, GP Graders has been one of the world leaders in fruit grading and sorting technology. With a mission to increase the competitiveness and profitability of its customers, GP Graders focuses on developing machinery that is fast, gentle, and accurate with the products. Its grading and sorting solutions are ideal for blueberries, cherries, small tomatoes and stone fruits.

Stuart Payne, Director for GP Graders, explains that traditionally, blueberries have been processed either by hand or by archaic mechanical machines that only achieved the simple process of getting fruit into containers.

“Our range of AirJet™ Graders with gpVision™ achieve near-perfect color and size separation that provides consistency and uniformity in each pack. State-of-the-art defect detection analysis also goes to work to identify damaged and flawed fruit for ejection before any degree of manual sorting is ever required, saving labour cost in the traditionally arduous process of manual sorting”, comments Payne.

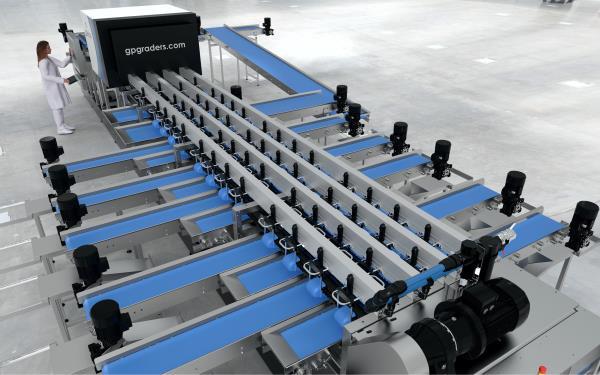

The AirJet® grader with gpVision™ is equipped with super high definition (HD) cameras, an advanced LED lighting arrangement, real time control unit and a complete firmware, software and user interface solution.

There is a range of graders in various sizes, capacities and configurations to suit different pack-house requirements.

“What distinguishes the AirJet® Grader with gpVision™ from other solutions in the market, is that this is the only machine capable of determining relative degrees of softness/firmness of blueberries. The software allows the product to be separated into 5-7 categories of softness to firmness. gpVision™ was designed with ease-of-use at the forefront of our objectives and feedback from our clients thus far supports the notion that we've achieved this. Our user interface is one of the most user friendly and intuitive systems to use. Graphically driven with a logical layout, users can be up and running in a matter of hours rather than days. Because we produce a range of machines that are built in a modular style, scalability is a key feature of our machinery. Our machines can be modified, expanded on and upgraded as your business develops. As such, we're able to cater to small pack-house requirements right through to large scale pack-houses processing 20 metric tonnes per day”, assures Payne.

According to the experience of Australian blueberry orchardist, David Mazzardis (Yanchep Springs), the AirJet® Blueberry Grader is capable of processing nearly 100 different blueberry varieties without having to change programs each time, which almost completely removes the need for a technician to operate the machine.

According to Payne, GP Graders recently made impressive advancements with cherry tomato defect detection. One high volume cherry tomato producer in Central Queensland is processing nearly 3 tonnes per hour with a minimum of a 30% daily labour reduction thanks to the effectiveness of gpVision™ defect detection. Tomatoes with splits, scars, shrivel or stems, plus a range of other defects, are being identified and ejected well before arriving at any manual sorting table.

In the near future, GP Graders will install a new AirJet Blueberry Grader gpVision near Warsaw in Poland. Complemented with A&B Infeed & Packaging solutions, its 8 lane grader will be processing up to 1200kg an hour for one of the most reputable family farms.

For more information about GP Graders, see the website