TOMRA will introduce innovative sorting solution and reliable aflatoxin detection technology for the hulling and shelling sector

VV

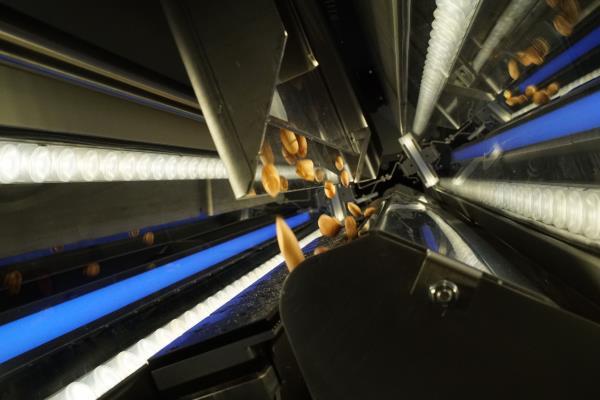

At the Almond Conference 2019 in Sacramento, California (December 10-12) TOMRA Food will demonstrate the TOMRA 3C, the new sensor-based optical sorter, which the company positions as a game changer for almond hulling and shelling operations. TOMRA Food will also take part in the panel discussion “Sorting for Aflatoxin” on December 11.

Brendan O’Donnell, Global Category Director – Nuts at TOMRA Food shares that the TOMRA 3C is equally valuable in cleaning product in the huller, hash recovery and inshell. “This means hulling and shelling operations will be able to deliver high quality products to processors, who in turn will benefit from a consequent increase in overall efficiency.” Further information on TOMRA 3C benefits and results is here.

Laragon Almond Processors, Australian almond huller and sheller, has recently tested the TOMRA 3C in their inshell almond operation. The company reported sorter has exceeded their high expectations with outstanding performance in food safety, waste and yield optimization – even replacing one of their existing inshell sorters. Detailed information about company’s experience and results can be seen here.

Another innovation to showcase is unique Detox Laser technology, manufacture states it has an excellent success across the world with its accurate detection of aflatoxin contamination. Detox Laser technology recognizes aflatoxin in nuts, peanuts, almonds, hazelnuts and dried fruits such as figs. It uses a special optical design that allows the detection and removal of aflatoxin contamination. This laser technique captures the extremely low intensity of light reflected by the fungus.

“Every country checks for aflatoxins by testing samples of the product, but this is not a dependable method as aflatoxin tends to be located in pockets, or ‘hotspots’, - explains Brendan O’Donnell. Reliable detection of aflatoxins can have a big impact on a processor’s business: “Accurate detection mitigates the extra costs, labor and handling – and the disruption to the plant’s operation – incurred whenever a shipment is rejected for contamination by aflatoxins. A rejection is not only expensive, but could also negatively affect the reputation and brand image of the processor. At TOMRA, we have analyzed the issue and developed a solution, which has proven its extreme reliability in detecting aflatoxins in various operations, and the only true way to know every almond is inspected by the TOMRA Detox technology.”

Follow here for the experience of Spanish Almond processor Crisolar, which has been using TOMRA’s Detox machine and shares excellent results.

Brendan O’Donnell will share his expertise on detection of aflatoxins in the panel discussion “Sorting for Aflatoxin – The Needle in the Haystack”, which will be held at the Almond Conference on December 11 at 8 am in Building C, Room 1.